May 24, 2016

- MEMORANDUM FOR:

- REGIONAL ADMINISTRATORS

- THROUGH:

- DOROTHY DOUGHERTY,

Deputy Assistant Secretary

- FROM:

- DEAN MCKENZIE, Acting Director

Directorate of Construction

- SUBJECT:

- Confined Spaces Litigation Settlement

This memorandum sets forth guidance regarding the application of 29

CFR 1926 Subpart AA to residential construction work. The following

Frequently Asked Questions (FAQs) clarify the scope of the standard, as

well as how the standard will apply to attics, crawl spaces, basements,

and other potential confined space or permit-required confined space

exposures that may occur during the course of residential construction

work. Finally, these FAQs address the standard's multi-employer

communication requirements and several questions regarding general

applicability of the rule.

These FAQs will be posted to the OSHA website and will be included in

any enforcement directive for the confined spaces in construction

standard.

Confined Spaces in Construction Qs and As

SCOPE

Question 1: What is a confined space?

A: A confined space means a space that (1) is large enough and so

configured that an employee can bodily enter it; (2) has limited or

restricted means for entry and exit; and (3) is not designed for

continuous employee occupancy (see 29 C.F.R. 1926.1202). All three

criteria must be met in order for a space to be considered a confined

space and covered by the Confined Spaces in Construction Standard

(hereinafter "Confined Spaces in Construction Standard" or "Standard").

Question 2: What is a permit-required confined space?

A: A permit-required confined space or permit space means a confined

space that has one or more of the following characteristics: (1)

contains or has the potential to contain a hazardous atmosphere; (2)

contains a material that has the potential for engulfing an entrant; (3)

has an internal configuration such that an entrant could be trapped or

asphyxiated by inwardly converging walls or by a floor which slopes

downward and tapers to a smaller cross-section; or (4) contains any

other recognized serious safety or health hazard (see 1926.1202).1

Question 3: Paragraph 1926.1203(a) requires that each

employer ensure that a competent person identifies all confined spaces

in which one or more of the employees it directs may work, and

identifies each space that is a permit space, through consideration and

evaluation of the elements of that space, including testing as

necessary. If the competent person must enter the space to assess its

characteristics and potential hazards, must the competent person treat

the space as a permit-required confined space?

A: If the competent person can reasonably foresee the presence of a

hazard or potential hazard that would make the space a permit-required

confined space (see response to Question 2), the competent person must

treat the space as a permit-required confined space when entering the

space to assess it. However, if the competent person cannot reasonably

foresee the presence of such a hazard, the competent person would not

need to treat the space as a permit-required confined space when

entering the space to assess it. Of course, if the competent person

encounters such a hazard when assessing the space, whether or not the

hazard was reasonably foreseeable, the competent person must treat the

space as a permit-required space after identifying the hazard.

Question 4: Does the Standard impose additional requirements

on "permit-required confined spaces" beyond those imposed for "confined

spaces"?

A: Yes. In fact, the vast majority of the Standard's requirements

only apply to permit-required confined spaces, and attics, basements,

and crawl spaces in a residential home will not typically trigger these

requirements. Once the employer's competent person2

performs an initial evaluation and determines that a confined space

does not require a permit (1926.1203(a)), the employer's only further

obligations under the Standard are to have a competent person reevaluate

the space and, if necessary, reclassify it as a permit-required

confined space if changes in the use or configuration of the space occur

that could increase the hazards or potential hazards to entrants or if

the employer has any indication that the initial evaluation may have

been inadequate (1926.1203(f)).

If the employer's competent person determines that the space is a

permit-required confined space, the following provisions also apply:

entry communication and coordination (1926.1203(h)), permit-required

confined space program (1926.1204), permitting process (1926.1205),

entry permit (1926.1206), training (1926.1207), duties of authorized

entrants, attendants, and entry supervisors (1926.1208-1210), and rescue

and emergency services (1926.1211).

Question 5: Does the characteristic "contains or has the

potential to contain a hazardous atmosphere" in the definition of

"permit-required confined space" refer only to those atmospheres which

pose an acute hazard?

A: Yes. Where employees are exposed to hazardous atmospheres that do

not present an immediate danger of death or impairment that could impede

the employee's ability to exit the confined space without assistance,

OSHA's health standards for those hazards apply, rather than the

Confined Spaces in Construction Standard (see 1926.1202 definition of

"hazardous atmosphere").

Question 6: In some residential home building3

projects, the home builder constructs multiple homes with the same or

similar basic configuration. If the presence or absence of any potential

hazard in an attic, crawl space, or basement is known, does the

Standard require a competent person to examine each attic, crawl space,

or basement in each home to make a determination as to whether the space

is a permit-required confined space?

A: No. The standard requires a competent person to identify all

permit-required confined spaces in which employees may work "through

consideration and evaluation of the elements of that space, including

testing as necessary." 1926.1203(a). If a competent person can reliably

determine whether attics, crawl spaces, or basements with the same or

similar configuration contain one of the hazards or potential hazards

listed in response to Question 2 without physically inspecting each of

the spaces, the competent person need not physically examine each space

to make the identification required under 1926.1203(a).

GENERAL QUESTIONS ON ATTICS, CRAWL SPACES, AND BASEMENTS

Question 7: Does the mere presence of a physical hazard in an

attic, crawl space, or basement (before steps are installed) make the

space a permit-required confined space under the Standard?

A: No. However, if the attic, crawl space, or basement (before steps

are installed) is a confined space, the presence of a physical hazard in

the space would trigger the permit-required confined space requirements

if the physical hazard is not isolated4

(see 1926.1203(g)) or if there is potential employee exposure to the

physical hazard. Note that not all unsafe conditions constitute

"physical hazards," which the standard defines as only those conditions

that could impede an entrant's ability to exit the space without

assistance.

Question 8: Does the presence of electrical equipment in an

attic, crawl space, or basement (before steps are installed)

automatically make the attic, crawl space, or basement (before steps are

installed) a permit-required confined space?

A: No. Only if an entrant has exposure to a serious hazard associated

with the electrical equipment, such as an exposed live conductor, and

the exposure could impede the entrant's ability to exit the space

without assistance, would the presence of electrical equipment make the

attic, crawl space, or basement (before steps are installed) a

permit-required confined space.

Question 9: Is a dimly lit attic, crawl space, or basement

(before steps are installed) necessarily a permit-required confined

space?

A: No. A confined space with limited lighting alone would not be

considered a permit-required confined space, provided that the limited

lighting could not impede an entrant's ability to exit the space without

assistance.5

Question 10: Does the mere presence of animals in an attic,

crawl space, or basement (before steps are installed) that is a confined

space automatically make the attic, crawl space, or basement (before

steps are installed) a permit-required confined space?

A: No. The presence of animals would only make a confined space a

permit-required confined space if the animals posed a physical hazard,

as defined by the standard.

Question 11: Does the presence of water in an attic, crawl

space, or basement (before steps are installed) that is a confined space

always make the attic, crawl space, or basement (before steps are

installed) a permit-required confined space?

A: No.

Question 12: Are attics, crawl spaces, or basements (before

steps are installed) containing utility service lines (e.g., water,

natural gas, fuel oil, sewage, steam and electric power) that pass

through them always considered to be permit-required confined spaces?

A: No. If utility services pass through attics, crawl spaces, or

basements (before steps are installed) that are confined spaces, the

inherent hazards of the material flowing through the service lines do

not have to be considered in the permit space determination unless it is

reasonably foreseeable that a rupture or leak could occur such that the

contents of the service lines could cause a serious safety or health

hazard that could impede an entrant's ability to exit the space without

assistance.

SPECIFIC QUESTIONS ON ATTICS

Question 13: Are all attics in a residential home considered confined spaces under the Standard?

A: No. A confined space is a space that (1) is large enough and so

configured that an employee can bodily enter it; (2) has limited or

restricted means for entry and exit; and (3) is not designed for

continuous employee occupancy. All three criteria must be met for an

attic to be considered a confined space. In many instances, an attic

will not be considered a confined space because there is not limited or

restricted means for entry and exit. For example, attics with a

permanent, full-size doorway and/or stairwell access would rarely6

meet the definition of a confined space, provided there are no other

impediments to egress. An attic under construction where there is no

drywall in place would also not have limited or restricted means for

entry or exit and would not be considered a confined space.

Question 14: Are attics that are confined spaces generally considered permit-required confined spaces?

A: No. Attics that are determined to be confined spaces would

generally not be permit-required confined spaces because they typically

do not contain the types of hazards or potential hazards that make a

confined space a permit-required confined space (see response to

Question 2).

Question 15: Does the presence of a fall hazard alone in an attic make an attic a permit-required confined space?

A: No. A fall hazard in an attic - such as falling through the

drywall of the attic - could cause a serious injury. However, fall

hazards within an attic would not generally impede the ability of an

entrant to exit the space without assistance and therefore would not

trigger the permit-required confined space requirements. OSHA notes that

even though permit-required confined space requirements would not be

triggered in this situation, employers would still be obligated to

protect their employees from fall hazards - as appropriate and required -

when they are working in an attic where fall hazards exist.

Question 16: Does the presence of a mechanical fan in an attic automatically make the attic a permit-required confined space?

A: No. The presence of a mechanical fan would only make the attic a

permit-required confined space if it is reasonably foreseeable that the

fan could cause an injury that could impede an entrant's ability to exit

the space without assistance.

Question 17: Does the presence of asbestos in an attic make the attic a permit-required confined space?

A: No. Asbestos would not trigger the permit-required confined space

requirements of the Standard. However, if asbestos were present in an

attic, an employer would need to follow any applicable requirements of

OSHA's asbestos standards.

Question 18: When does an employee perform an "entry" into an attic for purposes of the Standard?

A: The Standard defines "entry" as the action by which any part of a person passes through an opening into a permit-required confined space.

Thus, regardless of whether or not such action is intentional or any

work activities are actually performed in the space, if any body part of

an entrant breaks the plane of an attic opening, that would constitute

an entry under the Standard, provided that the attic also meets the requirements of a permit-required confined space.

Question 19: In the residential home building industry,

frequently an employee will need to perform a final inspection of an

attic before turning over a home to a home owner. This inspection is

often of limited duration. Does this inspection constitute an "entry"

into a permit-required confined space under the Standard if there is no

reasonably foreseeable hazard present?

A: No. A final inspection of an attic would rarely constitute an

"entry" because even if an attic were a confined space, it would not

normally contain any of the hazards or potential hazards that would

trigger the permit-required confined space requirements of the Standard:

(1) contains or has the potential to contain a hazardous atmosphere;

(2) contains a material that has the potential for engulfing an entrant;

(3) has an internal configuration such that an entrant could be trapped

or asphyxiated by inwardly converging walls or by a floor which slopes

downward and tapers to a smaller cross-section; or (4) contains any

other recognized serious safety or health hazard (see 1926.1202). An

entry employer may rely on a competent person's expertise and experience

in determining whether the presence of such a hazard or potential

hazard is reasonably foreseeable during such an inspection or any other

time when it is necessary to enter into an attic that is a confined

space. If the attic is a permit-required confined space, the

employer must comply with the permit-required confined space provisions

of the Standard whenever there is an entry regardless of the duration of

the entry.

The same analysis would apply to other inspections conducted by

employees either at the outset of a construction project or as the

project progresses. If there is no reasonably foreseeable hazard or

potential hazard present in an attic or any other space during the

construction process, the permit-required confined space requirements

would not be triggered.

Question 20: How hot must it be in an attic that is a

confined space for the attic to be considered a permit-required confined

space under the Standard?

A: Extreme heat can be considered a serious physical hazard in attics

such that the attics could be considered permit-required confined

spaces. OSHA has not quantified how hot it must be to trigger the

permit-required confined space requirements. However, the heat must be

so extreme that it could potentially impede an entrant's ability to exit

the attic without assistance. Factors that the Agency would consider

are (1) the temperature of the space while work is performed, (2) the

nature and duration of the tasks performed in the heat, and (3) whether

the entrant is acclimatized to work in extreme heat. A short-duration,

light-duty task performed in a hot attic would typically not constitute a

physical hazard triggering the permit-required confined space

requirements. In addition, measures to control the heat in an attic

(e.g., use of a fan) will be considered by the Agency in determining

whether a serious hazard exists in the first instance.

Question 21: Many new residential homes are constructed with

pull down stair access to the attics, often referred to as "disappearing

attic stairways." For attics that use this type of stair access, would

OSHA consider the attics to be confined spaces?

A: Whether an attic with pull down stair access would be considered a

confined space depends on whether the configuration of the stairs

impedes the ability of employees to exit the space. Ladder-like pull

down stairs that require employees to ascend/descend hand-over-hand,

limit egress and could therefore render an attic a confined space. An

attic that can be accessed via pull down stairs that resemble the

structure of a stationary stairway and do not require an employee to

ascend/descend hand-over-hand would not be considered a confined space

if there are no impediments to egress.

Question 22: During some residential home building projects,

employees may be performing work activities in an attic with no

atmospheric or physical hazards present. However, after starting work,

another crew of employees may perform activities outside of the space

(e.g., painting or staining parts of a home outside of the attic) that

could impact conditions in the attic. Does the performance of duties

outside of an attic typically turn a "confined space" into a

"permit-required confined space"?

A: No. The performance of duties outside of an attic would only turn a

"confined space" into a "permit-required confined space" if the work

outside of the attic could create a hazardous atmosphere or physical

hazard in the attic that could impede the ability of an entrant to

safely exit the space without assistance. It would be rare for this to

occur in the residential home building environment. For example, the use

of portable power tools outside of an attic will rarely, if ever,

create a noise hazard such that it would impede the ability of an

entrant to safely exit the attic without assistance. Similarly,

performing painting and staining outside of an attic will rarely create a

hazard that would impede the ability of an entrant to safely exit an

attic without assistance. However, using certain high VOC (volatile

organic compound) solvents in paint thinners or in floor stripping could

potentially create a hazardous atmosphere in an adjacent attic or other

confined space.

Question 23: During remodeling work on residential homes, the

remodelers will often need to enter a confined space to assess certain

aspects of the construction of the home (e.g., electrical wiring,

location of plumbing lines, etc.). Do employees performing this initial

assessment have to follow the permit-required confined space

requirements of the Standard?

A: A competent person must assess these spaces to determine whether

they are permit-required confined spaces prior to any entry. The

employer will only need to follow the requirements of a permit-required

confined space program if, based on the competent person's assessment,

the employer has reason to believe the space is a permit-required

confined space. It would be rare that a remodeler would need to follow

the permit-required confined space requirements in this situation

because most confined spaces in a residential home will not contain the

hazards that would trigger the permit-required confined space

provisions: (1) contains or has the potential to contain a hazardous

atmosphere; (2) contains a material that has the potential for engulfing

an entrant; (3) has an internal configuration such that an entrant

could be trapped or asphyxiated by inwardly converging walls or by a

floor which slopes downward and tapers to a smaller cross-section; or

(4) contains any other recognized serious safety or health hazard (see

1926.1202).

Question 24: If an HVAC unit in an attic that is a confined

space needs repair, requiring a contractor to enter the attic to perform

certain activities to fix the unit, is that entry into the attic

covered by OSHA's Confined Spaces in Construction Standard?

A: No, provided the repair is considered maintenance work on the unit

(covered by the general industry standards) such as adjusting existing

equipment or replacing component parts in kind. However, upgrading the

HVAC system or its component parts would be considered construction work

covered by the Standard.7 This would also be the case for any other piece of equipment in an attic that is a confined space.

Question 25: Some attics in residential homes are accessed

through standard door openings, which include the following dimensions:

24" x 80"

30" x 80"

32" x 78"

32" x 79"

32" x 80"

34" x 80"

36" x 78"

36" x 79"

36" x 80"

38" x 82"

42" x 80"

60" x 80"

64" x 80"

68" x 80"

72" x 80"

74" x 96"

For attics with entry doors of standard dimensions, such as

those listed above, would OSHA consider the attics to be confined spaces

under the Standard, assuming there are no other impediments to

access/egress on or around the entrance?

A: No. Attics with full-sized doors at least two feet in width and

six feet, six inches in height would not meet the definition of a

confined space, provided the path to the entrance and area around the

entrance are kept clear of structural or temporary impediments to

egress.

Question 26: Is the contractor who creates a permit-required

confined space responsible for placing a warning sign on or around the

entrance to the space warning of the existence of a permit-required

confined space?

A: Only an employer that should reasonably anticipate that the

employees it directs may enter a permit-required confined space is

required to post a sign or other equally effective means to warn

employees of the location of and danger posed by the permit-required

confined space. For example, if a contractor affixes drywall to the roof

trusses of a residential home and creates a confined space, that

contractor is not required to post a warning sign that the attic

constitutes a permit-required confined space, unless (1) the attic meets

the criteria of a permit-required confined space, and (2) the

contractor should reasonably anticipate that the employees it directs

may enter the attic.

Question 27: Is the permit for a permit-required confined space required to be posted?

A: No. However, the permit must be "made available" at the time of

entry to all authorized entrants or their authorized representatives.

This requirement to make the permit available could be met by posting

the permit or by "any other equally effective means" (see 1926.1205(c)).

SPECIFIC QUESTIONS ON BASEMENTS

Question 28: Is a basement in a residential home that is

designed for continuous occupancy by a homeowner a confined space under

the Standard?

A: No, provided the basement is configured as designed (e.g., has

permanent stairs, walk-out entry/exit, or egress window installed).

Question 29: Before a set of stairs is installed in a

residential home into a basement, home builders may access the space

through a walk-in door to/from the outside (i.e., walk-out basement).

Under these circumstances, would the basement be considered a confined

space?

A: No. Provided there is a door to/from the outside to the basement,

the basement would not be considered a confined space as there would not

be limited or restricted means of egress.

Question 30: In some homes, before a set of stairs is

installed into a basement, home builders may access the space through a

basement egress window that complies with Section R310 of the 2012 or

2009 International Residential Code. Under these circumstances, would

the basement be considered a confined space?

A: No. If the basement has an egress window that meets the

specifications of Section R310 of the 2012 or 2009 International

Residential Code, the basement would not be considered a confined space

as there would not be limited or restricted means of egress to and from

the basement.

OTHER SPACES IN RESIDENTIAL HOMES

Question 31: There are some spaces in a residential home that

may technically meet the definition of a confined space, but there is

no reasonably foreseeable hazard within the space that could impede an

employee's ability to exit the space without assistance. Examples of

this would be a small pantry or a small space underneath a stairwell in a

home. Are these spaces considered permit-required confined spaces under

the Standard?

A: No. Even if the space is a confined space (see response to

Question 1), if there is no reasonably foreseeable hazard or potential

hazard within a space that could impede an entrant's ability to safely

exit the space without assistance (see response to Question 2), then a

residential home builder would not be required to consider the space a

permit-required confined space under the Standard. A residential home

builder may rely on a competent person's experience and expertise in

determining whether any such hazard or potential hazard in a space is

reasonably foreseeable.

MULTI-EMPLOYER COMMUNICATION PROVISIONS

Question 32: Do the multi-employer communication requirements

of 1926.1203(h)(1) of the Standard apply to host employers that do not

have employees who work on the worksite?

A: No. The requirements only apply to host employers with employees

who work at the worksite, regardless of when those workers are at the

site.

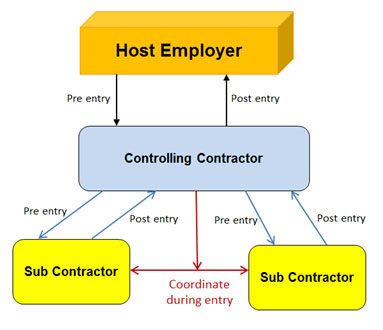

Question 33: Paragraph 1926.1203(h)(1) of the Standard

includes requirements for permit space entry communication and

coordination. It requires that before entry operations begin, the host

employer must provide the following information, if it has it, to the

controlling contractor: (1) the location of each known permit space; (2)

the hazards or potential hazards in each space or the reason it is a

permit space; and (3) any precautions that the host employer or any

previous controlling contractor or entry employer implemented for the

protection of employees in the permit space. Under the Standard, is the

host employer required to perform a separate assessment of all spaces to

gather the information required by this paragraph?

A: No. The Standard only requires the host employer to communicate

the information in paragraph (h)(1) if it is known by the host employer.

The Standard does not require the host employer to perform a separate

assessment to gather the information. In addition, the communication

provisions only require host employers to convey the information to the

controlling contractor through reasonable means. There is no requirement

in the standard for the host employer to verify that the information

has been received by the controlling contractor or transmitted to entry

employers by the controlling contractor. A host employer that has the

information in paragraph (h)(1) need only communicate the information to

the controlling contractor one time to satisfy the requirements of the

Standard. Additional communications will only be required if the host

employer gains additional such information not included in the original

communication.

Question 34: Are host employers/controlling contractors

responsible for compliance with the permit-required confined space

program provisions of the Standard if they have no reason to anticipate

that the employees they direct will enter a permit-required confined

space?

A: No. However, these employers must nonetheless (1) take effective

measures to ensure that the employees they direct do not enter any known

permit spaces (see 1926.1203(c)), and (2) comply with 1926.1203(h).

Otherwise, only employers that should reasonably anticipate that the

employees they direct may enter a permit space are responsible for

compliance with the permit-required confined space requirements of the

Standard. For example, employers that will not direct any employees to

enter a confined space are not required to comply with the following

provisions of the rule: permit-required confined space program

(1926.1204), permitting process (1926.1205), entry permit (1926.1206),

training (1926.1207), duties of authorized entrants, attendants, and

entry supervisors (1926.1208-1210), and rescue and emergency services

(1926.1211).

Question 35: Can a residential home builder serving as a host

employer or controlling contractor perform a single communication

(whether from a host employer to a controlling contractor or from a

controlling contractor to an entry employer) to fulfill its obligations

under 1926.1203(h) of the Standard provided there are no expected

deviations in the presence or absence of potential hazards in a confined

space in a home?

A: Yes. The Standard does not require multiple communications of the

information in paragraph (h) between employers on a residential home

building site (whether at a single home building site or a site with

multiple homes being constructed) where the potential hazards of

confined spaces remain the same or substantially the same as long as any

minor differences between the spaces are not relevant to which

provisions of the standard apply to the spaces. However, if a host

employer or controlling contractor learns of new information relevant to

assessing the space under the Standard after an initial communication,

the host employer or controlling contractor would need to convey the new

information in a subsequent communication.

Question 36: Does 1926.1203(h) necessarily require entry

employers to communicate the specified information before and after each

time an employee goes into an attic, basement, or crawl space that is a

permit-required confined space?

A: No. An entry employer must communicate the information required

under 1926.1203(h)(3) before "entry operations" begin, and it must

communicate the information required under 1926.1203(h)(5) after "entry

operations" have ended. Entry employees may go into and out of the space

multiple times while completing the tasks identified on the permit

without making additional communications as long as the entry employer

maintains control over the space between the pre-entry and post-entry

communications required under 1926.1203(h)(3) and (h)(5). In addition, a

single pre-entry communication could address entry operations in

multiple spaces under 1926.1203(h)(3) and a single post-entry

communication could address multiple entry operations under

1926.1203(h)(5), provided each space has its own permit and is addressed

in the communication.

Question 37: Do the communication provisions in 1926.1203(h) apply to non-permit confined spaces?

A: No. These provisions only apply to permit-required

confined spaces. Employers who have confined spaces - but not

permit-required confined spaces - are under no obligation to follow the

communication requirements of the Standard.

Question 38: Does the exchange of information set forth between employers in 1926.1203(h) have to be in writing?

A: No. OSHA does not specify how the information is to be exchanged.

The Agency will deem it sufficient for each employer to provide the

necessary information through any appropriate mechanism. The information

exchange requirements can be oral. There is no requirement in the

Standard for written communications between employers on multi-employer

worksites.

Question 39: If an employer chooses to exchange the required

information in writing under 1926.1203(h), can the written communication

be informal?

A: Yes. While the exchange of information does not have to be in

writing, some employers may choose to establish a mechanism for a

written exchange. The written exchange does not have to be formal. It

can be performed through email, text message, or other informal means,

so long as the required information is provided.

Question 40: Under 1926.1203(h), is the controlling

contractor under any obligation to enter a space to get information to

relay to a host employer or entry employer?

A: No. A controlling contractor only needs to obtain information on

permit-required confined spaces from the host employer and entry

employer(s) and provide this information and other known information on

permit-required confined spaces to a host employer or entry employer.

The Standard does not require a controlling contractor to enter spaces

to gather information.

Question 41: On multi-employer worksites, is every employer

responsible under 1926.1203(a) to assess the worksite to determine the

location and presence of confined spaces and information about

permit-required confined spaces?

A: No. Only employers that should reasonably anticipate that the

employees they direct may enter confined spaces are required to perform

this assessment. For host employers and controlling contractors that

have no reason to anticipate that the employees they direct may enter

confined spaces, there is no obligation to perform this initial

assessment of the worksite.

Question 42: Is a home owner who is not an employer covered by the Standard?

A: No. The Standard only applies to employers.

APPLICATION OF THE STANDARD

Question 43: Can an entry supervisor also serve as an attendant during an entry into a permit-required confined space?

A: Yes. An entry supervisor also may serve as an attendant or as an

authorized entrant, as long as that person is trained and equipped as

required by the Standard for each role he or she fills.

Question 44: The Standard defines isolate or isolation as

"the process by which employees in a confined space are completely

protected against the release of energy and material into the space, and

contact with a physical hazard, by such means as: blanking or blinding;

misaligning or removing sections of lines, pipes, or ducts; a double

block and bleed system; lockout or tagout of all sources of energy;

blocking or disconnecting all mechanical linkages; or placement of

barriers to eliminate the potential for employee contact with a physical

hazard." Is guarding by location an acceptable form of isolation under

the Standard?

A: Yes. Guarding by location-that is, configuring the space or

equipment in the space to eliminate employee exposure to the hazard-is

an acceptable form of isolation under the standard.

Question 45: OSHA has identified "noise" as a potential

physical hazard. What noise level must be reached in order to constitute

a physical hazard such that the permit-required confined space

requirements apply?

A: There is no specific threshold noise level that must be reached in

order for noise to constitute a physical hazard triggering the

permit-required confined space requirements. However, the noise must be

so extreme that it could impede an entrant's ability to safely exit the

space without assistance. In most instances, noise levels below the

eight-hour TWA permissible exposure limit for noise in construction of

90 dBA would not constitute a physical hazard triggering the

permit-required confined space requirements.

Question 46: If engineering and administrative controls

cannot be implemented in a residential homebuilding project to address

potential noise exposures, is it acceptable for a residential home

builder to rely on personal protective equipment to address noise

exposures for purposes of the Standard?

A: Yes. A residential home builder may rely on personal protective

equipment to address a noise hazard for purposes of complying with the

Standard so long as the personal protective equipment itself does not

serve to impede the ability of an entrant to safely exit the space

without assistance.

Question 47: If a competent person determines that a confined

space in a residential home does not contain or have the potential to

contain a hazardous atmosphere, would an entry employer need to conduct

atmospheric testing of the space before an entry and provide for

continuous monitoring of the space during the entry?

A: No. If a confined space does not contain or have the potential to

contain a hazardous atmosphere, an entry employer is not required to

perform atmospheric testing or atmospheric monitoring.

Question 48: In determining whether a space has limited means

of egress such that it would be considered a confined space, does the

size of the entry employee matter?

A: No. Whether a space has limited means of egress is a

fact-dependent determination based on the size of the entrance and the

configuration of the inside of the space. It is not dependent on the

size of an entry employee.

Question 49: Can OSHA cite an employer for not documenting the initial evaluation of the workplace required by 1926.1203(a)?

A: No. The initial evaluation need not be documented. The employer,

however, must be able to explain how the evaluation was conducted and

describe the results. Thus, any citation will be for failure to

evaluate the workplace as required by the Standard, rather than for

failure to create a record of the evaluation.

Question 50: Does the initial evaluation for determining if a

confined space is a permit space, required by 1926.1203(a), mandate a

specific physical survey of each space?

A: No. The evaluation requirement may be met through existing

experience and knowledge of the space, provided this information is

adequate to make the determination required by the Standard. For

example, a competent person may have information which shows that the

hazards or potential hazards of all attics, crawl spaces, and basements

(before steps are installed) will not impede an entrant's ability to

exit the space without assistance. Therefore, these spaces would not

need to be evaluated individually before each entry. This same approach

can be used for any entry employer which has a number of identical

spaces and information to support its determination(s). See the response

to Question 6.

Question 51: Under the Standard, which employer issues the permit for permit-required confined spaces?

A: The permit is issued by the entry employer (see 1926.1205(a) and

the definition of "entry employer" in 1926.1202: the "employer who

decides that an employee it directs will enter a permit space").

Question 52: If a rescue service fails to notify an entry

employer that the rescue service is unavailable, will the entry employer

be cited under the Standard?

A: No. So long as the entry employer informed the rescue service that

rescue services may be needed and of the requirement that the rescue

service notify the employer if it is unavailable for rescue, and the

rescue service agreed to provide the notification, no citation will

issue to the entry employer if the rescue service fails to fulfill its

agreement to notify the entry employer that it is unavailable to perform

rescue services.

Question 53: If an employer establishes a policy

prohibiting the employees it directs from working in a permit-required

confined space and effectively communicates the policy to those

employees, does that employer still need to have a rescue harness on

site and train the employees it directs in rescue operations?

A: No. Only employers that can reasonably anticipate that the

employees they direct may enter permit-required confined spaces are

subject to the requirement to develop and implement procedures for

rescue and emergency services under 1926.1204(i) and 1926.1211.

Question 54: In fulfilling the requirements of 1926.1203(a),

can a competent person rely on experience and past practice in terms of

assessing the existence of confined spaces and permit-required confined

spaces?

A: Yes. A competent person can draw from his or her experience and

expertise in making the required assessment under 1926.1203(a).

Question 55: What constitutes serious physical damage under the Standard?

A: Section 1926.1202 defines serious physical damage as an impairment

or illness in which a body part is made functionally useless or is

substantially reduced in efficiency. Injuries involving such impairment

would usually require treatment by a physician or other licensed

health-care professional. In general, injuries requiring only first-aid

treatment would not be considered serious physical damage because they

would not impair an employee's ability to safely exit a confined space

without assistance.

1

Under the Standard, the word "hazard" means either a "physical hazard"

or an "atmospheric hazard" as defined in the Standard. An unsafe

condition that does not meet the definition of "physical hazard" or

"atmospheric hazard" would not be considered a "hazard" under the

Standard or for purposes of this document.

2

A competent person means someone who is capable of identifying existing

and predictable hazards in the surroundings or working conditions which

are unsanitary, hazardous, or dangerous to employees, and who has the

authorization to take prompt corrective measures to eliminate them (see

1926.1202 definition of "competent person").

3

As used in these Qs and As, "residential home building" or "residential

home construction" refers to work on any residence being built using

traditional wood frame construction materials, methods, and procedures

that are typical to single-family home or townhouse construction.

Traditional wood frame construction materials and methods include (1)

framing materials - wood (or equivalent cold-formed sheet metal stud)

framing (not steel or concrete), wooden floor joists and roof

structures; (2) exterior wall structure - wood (or equivalent

cold-formed sheet metal stud) framing or masonry brick or block; and (3)

methods - traditional wood frame construction techniques (see OSHA's

Compliance Guidance for Residential Construction, STD 03-11-002 (June 6,

2011), available on OSHA's website). Work on multi-family residences

may also be considered "residential home building" or "residential home

construction" provided that the work similarly meets the criteria set

forth above.

4

For physical hazards, the Standard defines the term "isolate" as "the

process by which employees are completely protected against . . .

contact with a physical hazard, by means such as Blanking or blinding;

misaligning or removing sections of lines, pipes, or ducts; a double

block and bleed system; lockout or tagout of all sources of energy;

blocking or disconnecting all mechanical linkages; or placement of

barriers to eliminate the potential for employee contact with a physical

hazard." 1926.1202. Guarding by location is also an acceptable means

of isolation under the Standard (see response to Question 44).

5 Note, however, that dimly lit spaces can potentially pose other safety hazards, and lighting must comply with 29 C.F.R 1926.56.

6 See response to Question 21 regarding stairwell access to attics.

7

This response is consistent with OSHA's general policy on

distinguishing between general industry and construction work as

described in a Letter of Interpretation from OSHA to Raymond V. Knobbs

issued on November 18, 2003, available on OSHA's website.

(Ben Lambert/The Register Citizen) An underground heating oil tank at the Sons of Italy Hall, 34 Center St. in Torrington, which overflowed into the Naugatuck River, prompted a hazmat response in Torrington early Monday morning. Above, a team removes a combination of oil and water from the underground tank on Center Street.

(Ben Lambert/The Register Citizen) An underground heating oil tank at the Sons of Italy Hall, 34 Center St. in Torrington, which overflowed into the Naugatuck River, prompted a hazmat response in Torrington early Monday morning. Above, a team removes a combination of oil and water from the underground tank on Center Street.