FAILURE TO FOLLOW FREEZING WEATHER PROCEDURES, CAUSED A BIG

LOSS OF NATURAL GAS AND A HUGE FINE FOR CABOT OIL & GAS CORPORATION

The

Department of Environmental Protection (DEP) today announced it has fined Cabot

Oil & Gas Corp. of Pittsburgh $76,546 for a January well control incident

at the company’s Huston well pad in Brooklyn Township, Susquehanna County.

“Cabot

lost control of the Huston J1 gas well for 27 hours, to which the department

responded to promptly to ensure there were no significant environmental

impacts,” DEP Director of District Oil and Gas Operations John Ryder said. “In

this incident, mostly gas was released, which dissipated quickly to background

levels within 100 feet from the well.”

To read

more, please use this link:

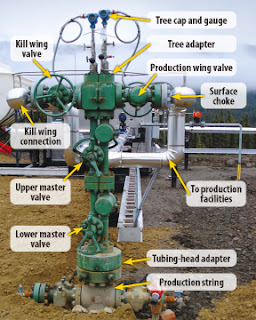

The

incident began the morning of Jan. 5 when a Cabot subcontractor was replacing

equipment on the wellhead. The

subcontractor did not follow standard operating procedures for the process by

failing to first warm the wellhead prior to conducting any work in the freezing

temperature. This resulted in damage to a wing valve.

A

subsequent analysis of the damaged wing valve indicated that it was in the open

position, allowing gas to escape. The analysis also indicated that frozen sand

in the valve bore may have obstructed movement of the gate, causing a function

test to indicate the valve was closed when it was open.

Cabot

contacted Wild Well Control of Houston, Texas, for assistance, which installed

two hydraulic valves to diminish the gas flow in the damaged valve to allow

full replacement. The well was brought under control shortly before 1 p.m. on

Jan. 6.

During

the incident, Cabot contacted five property owners within a quarter mile of the

well pad to notify them of the situation. However, it was determined that no

evacuation was needed based on the results of DEP air monitoring. DEP staff

used meters to detect combustible gas on and in the vicinity of the well pad,

and to determine if there was an explosive atmosphere.

DEP Oil

and Gas and Emergency Response program staff were on scene providing oversight

throughout the incident.

The

department issued a notice of violation (NOV) to Cabot on Jan. 16 for

violations of the Solid Waste Management Act, Clean Streams Law and the Chapter

78 oil and gas regulations. The NOV requested a written response within 10

days, which Cabot provided.

In its

response, the company said it could not determine the exact amount of natural

gas or fluid released because it was not possible to safely measure the flows,

but said the majority of the release consisted of natural gas.

Pennsylvania

hits another production record

Gas

production in Pennsylvania continued to hit records, with 1.9 trillion cubic

feet of gas coming out of the ground during the first half of the year,

according to new data released from the Pennsylvania Department of

Environmental Protection on Monday. That's a 14 percent increase over the

previous six-month period when operators pulled 1.7 trillion cubic feet of

gas out of the ground. A year ago it was closer to 1.4 trillion.

About

510 new wells came online during the reporting period.

Infrastructure

constraints in Appalachia have made it difficult for producers to get their gas

out of this underpriced market to hungry demand centers outside of

Pennsylvania, but some of that may be easing.

“There's

a lot of new capacity over the first half of the year," said Sam Gorgen, a

U.S. crude oil production analyst at the Energy Information Administration, who

monitors Pennsylvania oil and gas production.

"Certainly,

there is the possibility of companies wanting to bring on more wells, and there

could be some restrictions on [how much] they could flow from those

wells," he said.

Susquehanna

County had the most gas production during the past six months, with 455 billion

cubic feet, or 23 percent of the state sum. Bradford and Lycoming counties

followed.

In

southwestern Pennsylvania, Washington County continued to lead the area in gas

production with 198 billion cubic feet, followed closely by Greene County with

172 billion cubic feet. Production from the Greater Pittsburgh region accounted

for about a quarter of all statewide gas reported during the first six months

of 2014.

Washington

County was once again the leader in liquids production in the state by a large

margin, with 1.8 million barrels of condensate, most of that coming from Range

Resources, and 204,316 barrels of oil, all from Chesapeake Energy.

While a

distant second, Mercer County is starting to emerge as another liquids-rich

destination, with Shell and Halcon having some successes there with condensate

and oil. Last week, Shell sold off its acreage in Mercer and neighboring

Western Pennsylvania counties to Rex Energy Corp.

Five

Cabot Oil & Gas wells in Susquehanna County were the most productive during

the past six months, pumping out the most gas per day even though some had

already been producing for more than six months. Typically, a shale gas well

starts slowing production after only a few months.

The top

five producers in the state — Chesapeake Energy, Cabot Oil & Gas,

Range Resources, Southwestern Energy, and EQT Corp, in that order

— accounted for nearly half of the state's gas supply for the first

half of the year.

Metropolitan

Engineering, Consulting & Forensics (MECF)

Providing Competent, Expert and Objective

Investigative Engineering and Consulting Services

P.O. Box 520

Tenafly, NJ 07670-0520

Tel.: (973) 897-8162

Fax: (973) 810-0440

E-mail: metroforensics@gmail.com

We are happy to

announce the launch of our twitter account. Please make sure to follow us

at @MetropForensics

To unsubscribe from

future technical blogs and announcements, please reply to this email with the

word “unsubscribe” in the subject line.

Metropolitan appreciates your business.

Feel free to recommend our services to your

friends and colleagues.

We know you need to process damage claims

quickly and knowing the facts is now faster than ever – within 24 hours of site

visit. Our Pegasos Forensic Investigation Services (PFIS) feature:

·

Expert Forensic Investigators on-site.

·

Defensible, Readable, Conclusive Reports.

·

Fixed-Prices starting at $499 per chimney or roof

inspection (volume discounts are also available). Flood loss assessments

start at $999.0. HVAC equipment only inspections start at $299 for local

(within one hour one-way drive) assignments.

·

10-State Coverage Area.

All of our

employees and associates are subjected to full FBI background investigations

and security clearance.